PLANET

Our commitment to ensuring a sustainable future through every aspect of our business, respecting both the planet and people.

PACKAGING AND SERVICE MATERIALS

To effectively reduce environmental impact and actively commit to decreasing plastic waste, we are progressively replacing the use of virgin plastic materials with alternatives such as recycled PET or FSC-certified paper from sustainable forests.

SAES Coated Films

Innovative recyclable packaging for 1 kg chocolate bags, certified exclusively for Venchi. The coating of the see-through film captures oxygen, keeping the product fresh before opening.

Food&Beverage

All the Food and Beverage service materials used in our stores have been replaced with 100% compostable alternatives, including sugar cane fibre, PLA, MATER-BI and FSC-certified paper.

Shipping

We ship all orders placed at venchi.com in packaging made exclusively from renewable, recyclable, plastic-free and FSC-certified materials.

Packaging

We are gradually introducing naturally sustainable materials to package our products: cotton ribbons, packs and inner material made from FSC-certified paper, and aluminium chocolate wrappers.

To help protect the environment, check the packaging for its composition and consult the table to see how you can recycle it correctly.

ENERGY SAVING AND DIVERSIFICATION

In 2021, the amount of electricity used by our production facility fell by 50% compared to 2019 despite a 15% increase in the amount of chocolate we produced. This was possible thanks to the co-financing of the ROP Piemonte ERDF 2014-2020. We were able to make the following investments that have made us more efficient. Other investments include:

|

|

- Development of a renewable energy production and storage system: a project has been defined for the installation of five BESS charging units with a total capacity of 1,000 kW, enabling more efficient management of consumption peaks and improving the plant’s energy autonomy.

- In parallel, photovoltaic canopies will be installed over the plant’s internal and external parking areas, providing an additional capacity of 300 kWh. With these measures, the total nominal capacity of the photovoltaic system will exceed 1,100 kW. Both installations will be completed in the first half of 2025, further contributing to the reduction of CO₂ emissions.

- Optimisation of combined heat and power generation systems (cogeneration): the new control system has also been extended to the management of the boilers and the cogeneration plant at the site, which can generate 360 kW of electrical power at full load while recovering approximately 430 kW of thermal energy. The recovered thermal energy is fed back into production processes, improving overall plant efficiency and reducing the demand for primary energy.

- During the period under review, we launched a pilot project for digital energy management (Building Energy Management System – BEMS) in selected retail stores. This is an extension of the system installed at our Castelletto Stura production site, with the aim of monitoring and optimising energy consumption and therefore reducing CO₂ emissions.

- In 2024, we purchased Guarantees of Origin to offset 100% of the electricity purchased from renewable sources (for 2023 consumption). In 2025, we plan to offset 100% of the electricity purchased from renewable sources on a global level.

- In 2025, we reached a consumption of only 0.2 tonnes of oil equivalent per tonne of finished product: about half of what it was three years ago.

CO₂ Analysis

Starting in 2024, we began an important journey to measure our Group’s CO₂ footprint, using 2023 as the baseline year.

Heading

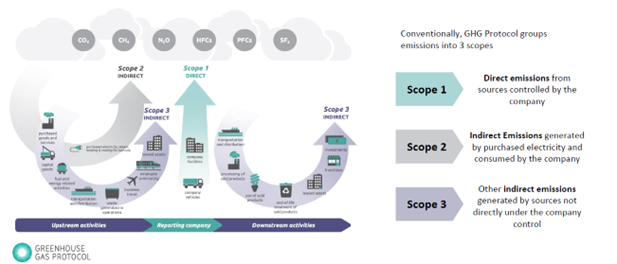

Our analysis covers Scopes 1, 2 and 3, therefore all emissions across the entire value chain (see Figure 1). We then repeated the same exercise in 2025: this allows us not only to identify the main emission hot spots, but also to monitor their evolution and assess the progress of our decarbonisation journey.

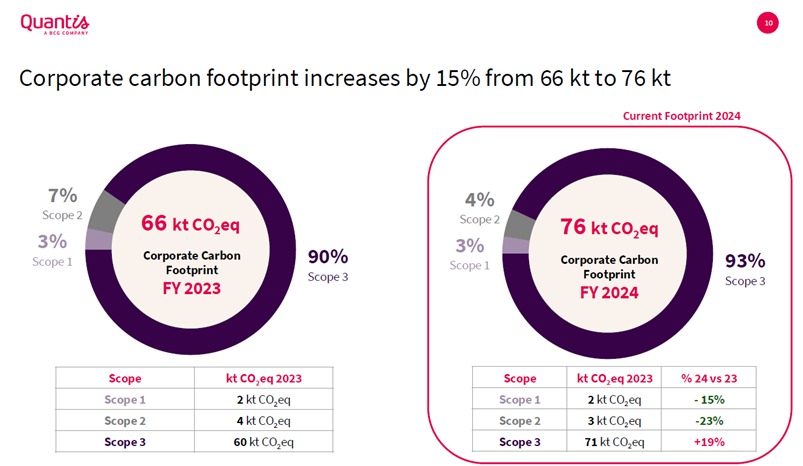

As a growing company, we recorded an increase in total emissions between 2023 and 2024. However, when looking at our direct perimeter — that is, Scopes 1 and 2 — we achieved a significant reduction: -15% for Scope 1 and -23% for Scope 2. These results are driven by the energy efficiency projects implemented at our plants and by the purchase of Guarantees of Origin (GOs) in Italy, which allow us to use 100% green electricity (see Figure 2).

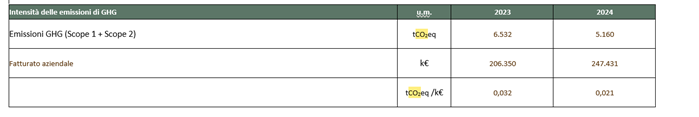

As shown in Figure 3, this translates into a reduction in emissions intensity of approximately -34% for Scopes 1 and 2.

Methodological note

We carried out the analysis in collaboration with our partner Quantis* and it was subsequently reviewed by EY, in line with the GHG Protocol guidelines.

*Quantis is a leading environmental sustainability consultancy that, with a scientific and pioneering approach, supports companies in measuring and reducing their impact in relation to planetary boundaries.

Figure 1

Figure 2

82% of our Scope 3 emissions come from raw material purchases. In 2024, our main raw material generated a carbon footprint of 37.5 kt CO₂e, equal to a +21% increase compared to the previous year, a figure linked to the growth of our production. To give a sense of the overall impact, 66 thousand tonnes of CO₂e are equivalent to the annual electricity consumption of 14,000 households or about 12% of the average annual CO₂ footprint of the population of Cuneo (56,000 inhabitants).

*Source: EPA Greenhouse Gas Equivalencies Calculator

**Source: Quantis, Venchi Corporate Footprint 2023

Figure 3

Legend

More information available here.

FSC: Forest Stewardship Council. More information available here.

PCR PET: Post-Consumer Recycled.

PLA: Polylactic acid or polylactide

MATER-BI: range of fully biodegradable and compostable bioplastics. More information available here.

BRCGS: Brand Reputation through Compliance. More information available here.

IFS: International Food Standard. More information available here.

Too Good To Go is a service that allows you to prevent unsold food from going to waste. More information available here.

Official document detailing the ethical commitments and responsibilities that apply when Venchi carries out its business.

The Italian Foundation for Cancer Research. More information available here.